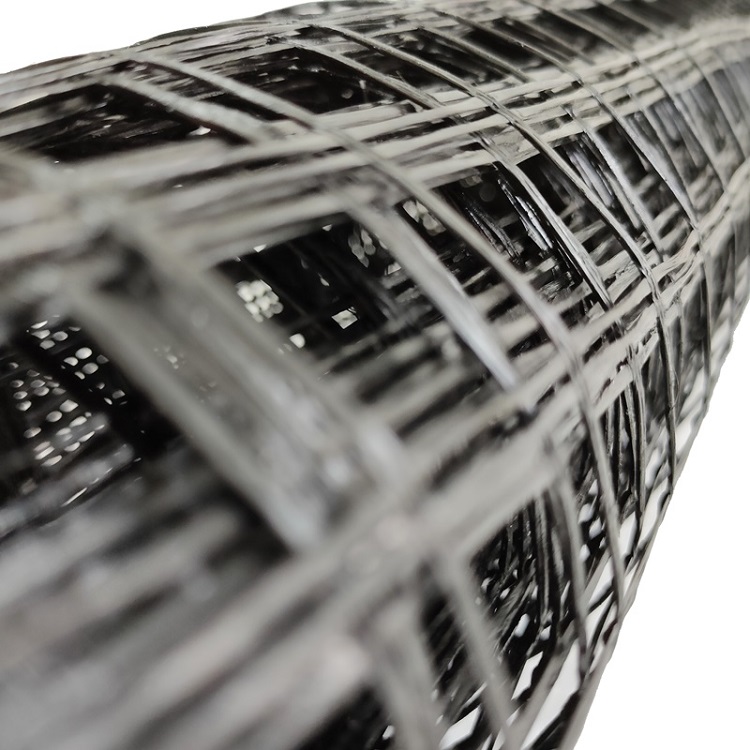

Fiberglass geogridA flat mesh structure material made by using alkali free glass fiber untwisted roving and woven into a substrate using a warp knitting machine, following a similar compatibility principle, and coated with modified asphalt. It adopts a warp knitted directional structure, fully utilizing the yarns between fabrics, and utilizing mechanical functions to provide it with high tensile strength, strength resistance, and creep resistance; Highlighting its composite function with asphalt mixture, it improves the wear resistance and shear resistance of the substrate.

As a new type of composite material, geogrid has advantages such as high strength, low elongation, and high strength. Its reinforcement effect is stronger than materials such as geotextile, and its application in reinforcement engineering is becoming increasingly widespread. Embedding the geogrid into the soil as a reinforcement material for the foundation can enhance its bearing capacity. Geogrids can restrain the lateral shear deformation of soil, improve the overall stress conditions of soil, and improve the overall strength of soil and the integrity of geotechnical structures.

After the roadbed is filled to the embankment, a layer of geogrid can be laid every other distance. Capable of handling large traffic flow. Design requirements for several dimensions, including a flat and dense roadbed and road surface. The spacing between the upper and lower layers of the geogrid should be smaller and smaller downwards, which will have a better effect. Energy saving, geogrids belong to the secondary resource utilization of the plastic industry, which is a product produced by adding shrinkage agents to waste plastic. As a road construction material, they are energy-saving and environmentally friendly, and their cost is also very cheap.

The difference between steel plastic geogrids is that of steel plastic geogrids. Through the management of the plastic surface in production engineering, the rolling of concave and convex patterns, the strength of welding points, and the surface coefficient of reinforcing bars, these effects enable the steel plastic composite geogrid to resist the horizontal shear force from the filler, and the bearing capacity of the soft foundation impedance the composition of the soil fracture surface, which meets the requirements of engineering construction.

Scope of application of geogrid:

1. Asphalt pavement for new construction and road expansion and renovation projects, reinforced with asphalt surface layer to prevent diseases

2. Renovation of old concrete pavement into composite pavement

3. Repair of cracks in asphalt pavement,

4. Repair of shrinkage cracks in semi rigid base.