Product Introduction:

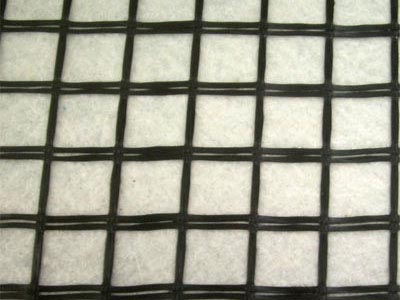

Composite geogrid is a composite of geogrid and geotextile** Three composite forms: geogrid is self-adhesive glass fiber geogrid or polyester geogrid, and geotextile is polyester filament geotextile; The second form of composite: the composite of bidirectional plastic geogrid and geotextile.

Product characteristics:

It has the characteristics of high tensile strength, low elongation, and uniform longitudinal and transverse deformation. It also has high water permeability, excellent filtration and wear resistance.

Main functions:

Road surface and roadbed reinforcement, filtration, drainage, protection, and isolation.

Engineering applications:

1. Used for enhancing road surfaces such as highways, railways, airports, etc.

2. Used for maintenance and widening of old road surfaces (asphalt pavement, cement concrete pavement).

3. Used for roadbed reinforcement.

Performance indicators:

Composed of geotextile and fiberglass geogrid or polyester geogrid. Additionally, the specific models of geotextile and geogrid can be customized according to requirements. The width of the geogrid is 1m-6m.

Geogrid composite geotextile is a new type of composite geotextile material made by weaving or bonding glass fiber or high-strength polyester fiber with non-woven fabric, which organically combines the excellent performance of both geogrids and geotextiles.

Features and performance:

1. High tensile strength and low elongation

2. High elastic modulus

3. Good temperature resistance

4. High permeability and filtration resistance

5. Tear resistance, anti detachment, and long service life

Product application:

Suitable for construction projects such as highways, railways, water conservancy, airports, ports, land reclamation, landfill sites, municipal construction, etc. It has multiple functions such as protection, isolation, filtration, reinforcement, seepage prevention, drainage, etc.

|

Technical parameters of composite geotextile

|

|||||||

|

classification

|

model

|

breaking strength(KN/m)

|

elongation at break(%)

|

mesh size(mm×mm)

|

width of cloth(m)

|

||

|

经向

|

纬向

|

经向

|

纬向

|

||||

|

glass fibre

Composite geotextile |

GGN30/150

|

≥30

|

≥30

|

≤4

|

≤4

|

12~50

|

2~6

|

|

GGN50/150

|

≥50

|

≥50

|

≤4

|

≤4

|

12~50

|

2~6

|

|

|

GGN80/150

|

≥80

|

≥80

|

≤4

|

≤4

|

12~50

|

2~6

|

|

|

Glass fiber grating

Composite geotextile |

GGM30/150

|

≥30

|

≥30

|

≤4

|

≤4

|

12~50

|

2~6

|

|

GGM50/150

|

≥50

|

≥50

|

≤4

|

≤4

|

12~50

|

2~6

|

|

|

GGM80/150

|

≥80

|

≥80

|

≤4

|

≤4

|

12~50

|

2~6

|

|

|

High strength polyester fiber

Composite geotextile |

GPN25/150

|

≥25

|

≥25

|

≤20

|

≤20

|

12~50

|

2~6

|

|

GPN50/150

|

≥50

|

≥50

|

≤20

|

≤20

|

12~50

|

2~6

|

|

|

GPN80/150

|

≥80

|

≥80

|

≤20

|

≤20

|

12~50

|

2~6

|

|

|

High strength polyester fiber grid composite

Geotextile |

GPM25/150

|

≥25

|

≥25

|

≤20

|

≤20

|

12~50

|

2~6

|

|

GPM50/150

|

≥50

|

≥50

|

≤20

|

≤20

|

12~50

|

2~6

|

|

|

GPM80/150

|

≥80

|

≥80

|

≤20

|

≤20

|

12~50

|

2~6

|

|

Remarks:

1. GGN and GPN are composite materials directly woven from fibers and geotextiles, while GGM and GPM are composite materials bonded with geotextiles after coating treatment.

2. The grid size is the grid size of fiber woven or grating.

3. The strength, width, and grid size of geogrids can be customized according to user requirements.