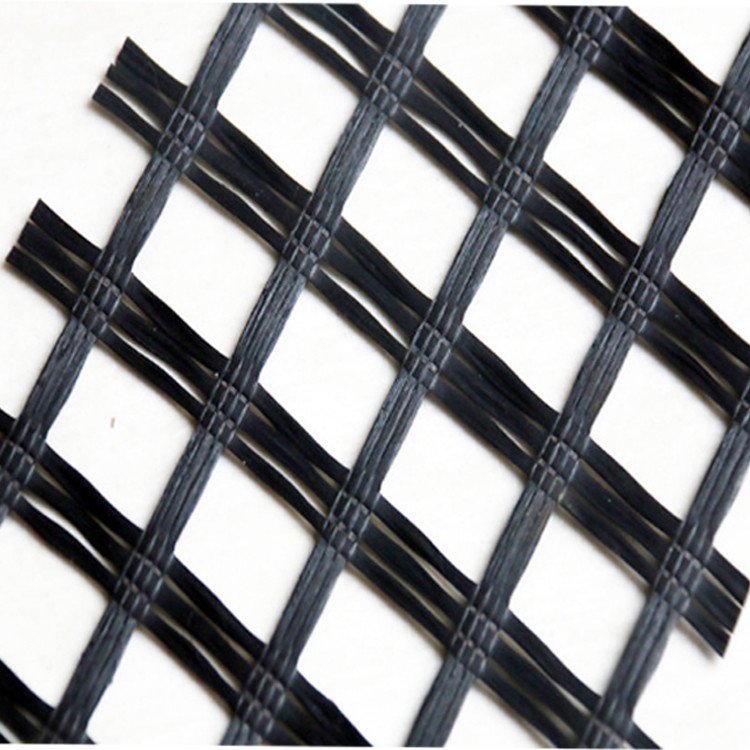

Fiberglass geogridIn normal engineering construction, the frequency of occurrence is relatively high due to its good usage effect. The editor of the fiberglass geogrid manufacturer will explain to us what should be paid attention to during laying, hoping to be helpful to you. Before laying, prepare in advance, develop relevant plans, prepare materials, and clean and level the site; The high-strength part of the fiberglass geogrid should be laid around the main load-bearing points on the road; The splicing between grids should be carried out in accordance with relevant regulations to reduce the occurrence of falling in the later stage.

When laying, there should be no wrinkles. After tightening, use some small tools to make the geogrid closely adhere to the road surface; If multi-layer fiberglass geogrids are laid, the connection points between the geogrids should be staggered, and the spacing between the upper base layers should be greater than half a meter; Before the project is completed, the fiberglass geogrid should not be subjected to excessive pressure, rolling, or conflicts. Before laying, remove any substances such as grease, water stains, dirt, etc. that may affect the bonding strength between the grille and the underlying layer from the old road surface to ensure a clean and monotonous surface. If there are water stains on the road surface, wait for the road surface to become monotonous before laying.

Special equipment is selected for grid laying and manual collaboration is carried out. Before starting the laying process, the adhesive surface should be selected downwards. During the laying process, it should be flat, tight, and not wrinkled, so that the grid has tension. After the laying is completed, a clean rubber wheel roller should be used to roll it again. During the rolling process, it should be noted that the water injection of the roller should not be too full to prevent overflow onto the fiberglass grid, causing its back and belly to lose adhesion. If it is found that there are small pits that have not been filled in advance, the corresponding part of the pits can be cut off on the laid grid, so that the pits can be filled in when laying the upper layer of asphalt mixture. When laying fiberglass geogrids, the road surface temperature is required to be between 10 and 60 ° C. The fiberglass grating should be fully covered with old concrete cement concrete pavement panels, and extend 1 meter into the new road surface at the junction of the new and old road surfaces.

The longitudinal overlap width shall not be less than 20cm, and the transverse overlap width shall not be less than 15cm. The longitudinal overlap shall be placed on top of the previous one according to the paving direction of the asphalt mixture. Use fixing nails and iron sheets or anchoring equipment from the manufacturer to fix the fiberglass grille. The fixed nails are made of cement, with a length of 8-10cm. The fixed iron sheet is made of 1mm thick and 3cm wide iron strips.