Fiberglass geogridIn daily engineering construction, the frequency is relatively high. Today, the editor will explain to you the areas that need to be paid attention to when laying, hoping to be helpful to you.

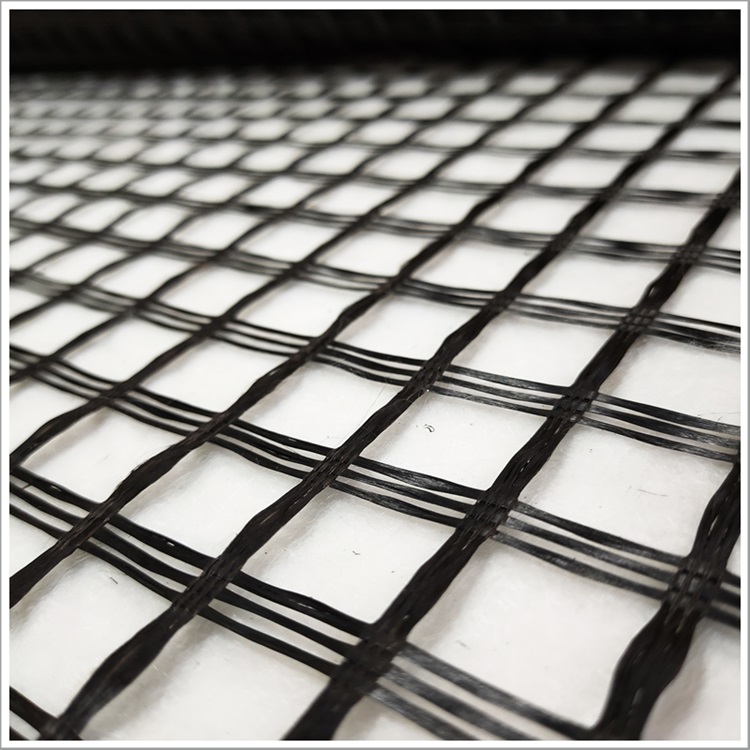

The usage rate of fiberglass geogrid has been increasing year by year. It can not only increase the strength of the road surface and extend the time it is available for us to use, but also has advantages such as corrosion resistance, high and low temperature resistance, good tensile performance, stable chemical and physical properties. Before construction, a detailed plan and drawings should be developed based on the on-site situation, and the site cleaning work should be done well. It is recommended to design the slope on the drawings in a ratio of 1:2, with a surface roughness of less than 5cm. After laying the filling materials, markings should be made; The soil block shall be treated with a hydraulic crusher, and the particle size shall be within 5cm. After crushing, the water content shall be adjusted according to the construction demand. The longitudinal axis of the glass fiber geogrid shall be vertical to the axial direction of the ditch or pavement.

When laying fiberglass geogrids, both sides should be tightened and fixed; There is a construction method called filling method, which refers to filling a layer of geogrid on top of the tensioned and fixed geogrid, and using a bulldozer to flatten it. It is important to avoid other vehicles rolling over the geogrid during the entire construction process, as it may cause varying degrees of damage and increase maintenance costs;

A variety of geotechnical materials are sold in the market, and with the continuous construction of major projects in recent years, many are still being used. Currently, the most popular material is fiberglass geogrid, which has some differences in the performance of materials produced by different manufacturers during use. This is also a problem that needs to be paid attention to when purchasing.

Before laying, prepare in advance, develop relevant plans, prepare materials, and clean and level the site; The high-strength part of fiberglass geogrid should be laid around the main load-bearing points of the road; The splicing between grids should be carried out according to relevant standards to reduce the occurrence of falling in the later stage; When laying, there should be no wrinkles. After tightening, use some small tools to make the geogrid closely adhere to the road surface; If multi-layer fiberglass geogrids are laid, the connection points between the geogrids should be staggered, and the distance between the upper and lower layers should be greater than half a meter; Before the project is completed, geotechnical materials should not be subjected to excessive pressure, rolling or friction.