The plastic protective mesh used underground in coal mines is a "dual resistance" plastic mesh independently developed by our company. This product is easy to construct, low in cost, and * * beautiful. Its main characteristics are that it is not easy to generate static electricity due to friction, has good flame retardancy, strong corrosion resistance, but is suitable for construction and transportation, is easy to clean coal, and has strong load-bearing capacity in both vertical and horizontal directions.

Product features: This product is a square mesh with a overall structure formed by using polypropylene as the main raw material, treated with flame retardant and anti-static technology, and subjected to biaxial stretching method.

1. Friction is not prone to generating static electricity. In the underground environment of coal mines, the average surface resistance of plastic mesh is 1 × Below 109 Ω.

2. Good flame retardancy. In an open flame environment, it only melts and does not burn, even if it burns for no more than 10 seconds before extinguishing.

3. Easy to wash coal. The density of this plastic mesh is around 0.92, which is less than the density of water. During the coal washing process, the broken mesh floats on the water surface and is easy to rinse off.

4. Strong corrosion resistance and aging resistance.

5. Convenient for construction and transportation. Plastic mesh is relatively soft and should not scratch workers during construction. It also has the advantages of easy curling, bundling, cutting, and light weight, making it easy to transport, carry, and construct underground.

6. Strong load-bearing capacity in both vertical and horizontal directions. The molecular structure of the plastic mesh after extrusion and stretching is reoriented, and the tensile strength of the material is 2-3 times of that before stretching. The bars and ribs formed by biaxial stretching are perpendicular to each other, which allows the pressure applied to the mesh surface to be effectively transmitted to the surrounding ribs through the nodes, thereby greatly improving the overall load-bearing capacity of the mesh surface. When an external force is applied to a certain tendon (or rib), it also evenly disperses the external force onto other tendons (or ribs), reducing the concentrated bearing capacity of a single tendon, thus making it less likely to cause the rib to fracture. In addition, due to the fact that this type of plastic mesh is biaxially stretched rather than woven, the creep of the mesh is small, and the mesh size is uniform, which can effectively prevent the falling of coal fragments and protect the safety of underground workers and the operation of mining trucks.

Product Usage: This product is mainly used as a support material for underground mining in coal mines, and can also be used as a support material for various tunnels such as anchor bolt tunnels, support tunnels, and anchor spray tunnels. When used for false roofs, it is necessary to use a combination of two or more layers.

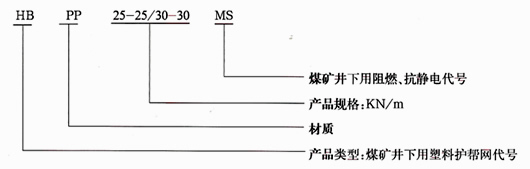

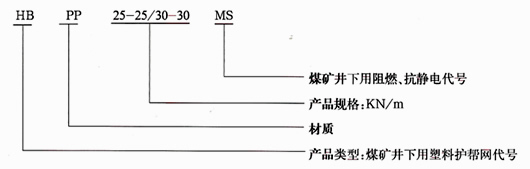

Product specifications: The composition and representative significance of the model:

|

Executive standard: Q/ZTJ · TG02-2006 "Plastic protective mesh for underground coal mines"

|

| Quality, size, and deviation of plastic protective mesh per unit area for underground coal mines

|

| project

|

HB PP25-25MS

|

HB PP30-30MS

|

| 2Mass per unit area g/m2

|

300±50

|

400±50

|

|

Roll length:m

|

5∽50(+0.5)

|

|

width:m

|

4.0/3.5/3.0/2.5/2.0/1.5/1.0

|

|

Width error:m

|

0~+0.20

|

|

Mesh edge length:mm

|

40(±5)×40(±5)

|

| Physical and mechanical properties of plastic protective mesh for underground coal mines

|

|

序号

|

project

|

单位

|

HB PP25-25MS

|

HB PP30-30MS

|

|

1

|

Longitudinal tensile force per linear meter

|

KN/M

|

≥25

|

≥30

|

|

2

|

Lateral tensile force per linear meter

|

KN/M

|

≥25

|

≥30

|

|

3

|

Longitudinal yield elongation

|

%

|

<25 |

|

4

|

Transverse yield elongation

|

%

|

<25 |